Examine This Report on Copper Foil

Wiki Article

The Ultimate Guide To Copper Foil

Table of ContentsCopper Foil - The FactsAll about Copper FoilThe Main Principles Of Copper Foil More About Copper FoilThe Only Guide to Copper FoilWhat Does Copper Foil Do?Not known Facts About Copper FoilThe Best Guide To Copper FoilThe Basic Principles Of Copper Foil

When you copper aluminum foil stained glass great deals of inquiries turn up that you weren't showed exactly how to deal with. Questions such as these: What size aluminum foil do I require? Exactly how do I keep discolored glass aluminum foil? Where do I start foiling on a piece? Scroll to locate a whole checklist of responses to assist improve your tarnished glass copper foiling.If you aim for the copper aluminum foil you'll be spot on. 3/16" 1/4" foil functions well for most typical copper aluminum foil tarnished glass items.

Copper Foil - An Overview

Copper Foil Can Be Fun For Anyone

The rolls fit completely and when the lid is protected in area, it helps maintain the foil. Begin hindering far from the perimeter of an item When you copper aluminum foil stained glass it's finest to begin foiling far from the outside edge as this produces more powerful adhesion. This is since the aluminum foil isn't joined on the outside edge where is is most likely ahead loose.

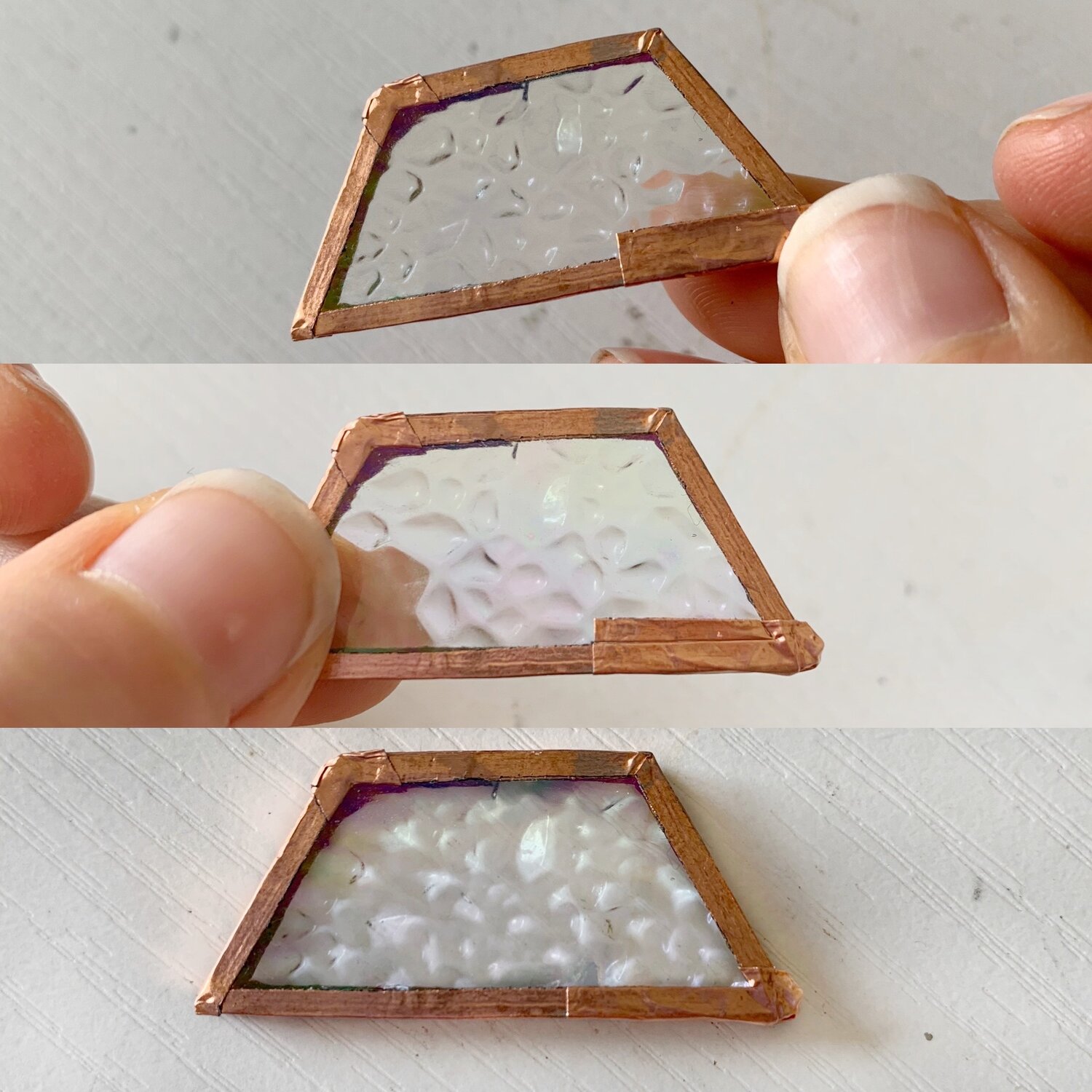

Do you understand just how to copper aluminum foil tarnished glass that is heavily textured? If you've tried this you'll recognize that the aluminum foil breaks as you attempt to go from high to low. Despite having shallow distinctive glass (surges) the aluminum foil in some cases breaks as it goes throughout the ripples rather of nicely contouring to it.

The Best Strategy To Use For Copper Foil

Make use of a cork for kinking distinctive glass as it is softer as well as supplies pressure while reducing tearing. A rubber eraser on the end of a pencil. It cleans up the aluminum foil as well! This benefits croc glass as well as various other very distinctive glass. Tilt the glass through the mill at an angle of 30-45 levels, flip it and do the same to the opposite side.Better still, you can make use of a to remove the hefty structure on the glass prior to foiling. Usage lined paper to help centre the copper aluminum foil When you copper foil discolored glass by hand it can be tough to centre the aluminum foil.

Copper Foil - Truths

Use lined paper as a guide! This is an interesting inquiry and also one I obtain asked A LOT. My solution may save you hrs of time grinding as well as cleaning. When you copper aluminum foil discolored glass you do not need to have a harsh surface for the foil to adhere to.Your shiny cut sides are great without grinding. Just read this beware of your fingers. You can simply mute the sharp sides off with a damp scythe stone to prevent reducing yourself and also to stop sharp edges reducing the aluminum foil. Ground edges need to be completely cleaned prior to hindering. Sometimes when you copper aluminum foil tarnished glass the foil leaves from the side.

The Facts About Copper Foil Uncovered

If you solder too slowly or go over the solder continuously the foil glue thaws and also comes to be unstuck. It's worth bearing in mind that the adhesive is there to hold the foil in area up until it's soldered.

If you tin the sides instead than developing a handmade side. "Tinning" suggests covering them with a thin coating of solder. "Beading" is a rounded edge of solder that 'clings' to the edge of the tarnished glass and is a lot more powerful.

Circuitry need is among the most vital motorists for electronic plan choice. The Semiconductor Market Association (SIA) (Sematech) releases a document on a normal basis to advise the industry of the here and now as well as future electrical wiring demand for a variety of item kinds. Table 1 reveals parts of the table that was released in look at more info 1999 (copper foil).

Copper Foil Fundamentals Explained

Lower I/O remain in hand held items that jeopardize on performance to attain their smaller dimension. These I/O worths are leading side applications with the biggest number of I/Os. Common applications have a lot lower need yet in time will capture up to the cutting edge needs, which are 510 years try this out in advance of the regular product.The various other item of the I/O formula is the size of the chip. This is mainly a function of exactly how lots of circuits are being used by the application.

Some Known Facts About Copper Foil.

In this technique, a gold or aluminum cord is bonded to a pad on the chip and also after that looped to a pad on the chip provider, which is the base for the module. A regular chip to substrate link using wire bond is noted in Fig. 1. With distinct cords, their placement can not be also close or the cords will touch each other.Report this wiki page